Aluminum Recycling

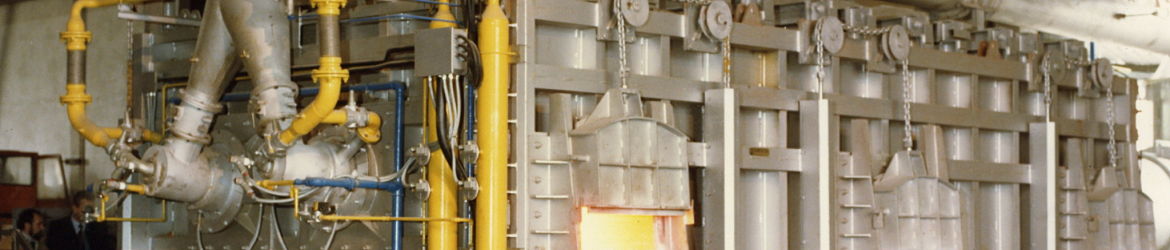

THE SCRAP RECYCLING SYSTEM

Secondary Aluminum production is based on the processing of varying qualities of scrap, amounting to some 40-45 different typologies (as per the institute of Scrap Recycling Industries - ISRI). the following categories are a summary of the various scrap feed:

- Sheets and Foils

- Used Beverage Cans

- Wires and Cables

- Pistons and Motors castings

- Extruded profiles

- Borings and turnings

- Dross, skimming and similar.

All materials pass through the phases of sorting, crushing, drying, de-coating, baling etc, in order to be suitable for the smelting and alloying operations.

In many cases the smelting occurs under a layer of salt (NaCl/KCl) in order to prevent oxidation. The resulting slag represents a waste by-product that must undergo through a dedicated recovery system.

THE STE PROCESS – TREATMENT OF ALUMINUM SALT SLAG

The Engitec proprietary technology for the secondary aluminum industry is the STE process for the treatment of aluminum salt slag. The process is suitable for large or for small productions and can be installed directly at the aluminum recyclers’ site.

The STE process allows the recovery of both residual aluminum and of the salt fractions, which is re-used in the smelting process. The fine clean oxides in the slag are recovered for use in other industrial applications such as cement manufacturing.

All polluting gases generated during the aluminum salt slag leaching are combusted and the heat generated is used for water evaporation and salt crystallization. No liquid effluents are released from the plant and the gaseous emissions are kept within regulatory limits.

INSPIRING INNOVATION

INSPIRING INNOVATION is the key Company Mission of Engitec, which is pursued daily by developing reciclying technologies to enable efficiency and environmental compliance.

Engitec Clients rely on the ability of the Company to minimize environmental impacts and can develop their solutions in partnership with Engitec, in order to minimize time to market and reduce costs.